A charged topic for the recycling industry is the imposition of metal tariffs for imports coming into the United States. Spring 2018 tariffs were set at 10% for aluminum and 25% for steel that is imported into the country. The directive of the tariffs is to protect production of domestic steel and aluminum, and allow U.S. developed steel and aluminum products to be competitive against foreign imports. This directive has left an uncertain future for many scrap metal recyclers in the United States.

The scrap metal industry has come onto some hard times for scrap pricing. Scrap steel and aluminum prices took sizable hits last year and continue to drop. Most scrap steel and aluminum prices have trended downward, and recycling rates have tended to decrease. For example, in mid-February 2019, scrap aluminum was selling for $1,473/metric ton on the London Metal Exchange, which is a 20% reduction in price from the year prior according to Bloomberg. The excess supply of iron ore in the United States has also caused steelmakers to opt out of buying scrap metal. However, many scrap owners feel the metal and aluminum prices have bottomed out and will slowly improve in the months ahead.

Scrap metal recyclers have a fairly standardized process and are always finding ways to improve, especially in these times when money is stretched. Scrap metal recycling centers buy used metals at prices set by the scrap market. It is then sorted at the recycling center by separating ferrous and non-ferrous metals. This can be done by applying magnets and identification by color. After sorting, the metals are shredded for ease in the melting process. The shredded metals are placed in a large furnace to be melted down and purified. These scrap products are then cooled, solidified, and formed into shapes like bars to be used in new products.

To offset some of the costs associated with a down market, recycling centers must have reliable equipment that drives the process of heavy processing of metal products. Cardinal Scale features a full line of heavy-capacity truck and floor scales for vehicle weighing and container weighing for recycling centers. Cardinal Scale offers the most effective technology and weighbridges to withstand such an unforgiving environment, while providing the value with continued use and resistance to breakdown.

For rail car weighing of scrap metals in aggregate form, Cardinal Scale’s LPRA railroad track scales are low-profile, feature a 270-ton capacity, extra-thick steel decks, and come in electronic or hydraulic load cells. The RSCA series truck and track scales are another great option for static weighing operations and have the combo application of weighing both rail cars and semi-tractor trailers. Designed with 270-ton capacity and 180-ton sectional capacity, featuring either electronic or hydraulic load cells, featuring weighrails that are sealed into the platform, and superior design to prevent sediment, moisture, and foreign materials, the RSCA is perfectly formulated for any bulk recycling weighing process. The LPRA and RSCA railroad scales provide NTEP legal for trade weighing of rail cars and containers distributing aluminum and steel scrap.

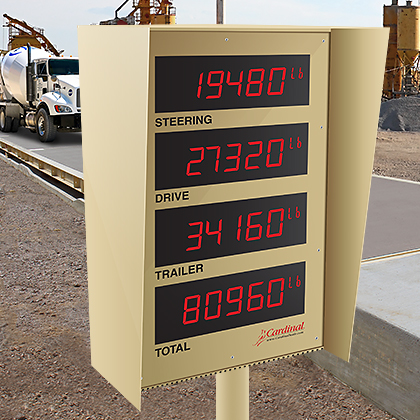

For scrap metal vehicle weighing, Cardinal Scale’s ARMOR truck scale line offers the newest technology combined with the strongest decks available. The ARMOR is available in checkered steel or pour-in-place concrete decks with 135-ton capacity and 50-ton CLC, no moving parts below the deck, SmartCell stainless waterproof load cells, and iSite load cell remote monitoring software. Additionally, Cardinal Scale’s ARMOR truck scales also feature hydraulic load cells which are perfect for environments like recycling and scrap yards. With recycling operations in mind, The SCRAPPER PSC series truck scale provides a precast concrete deck made specifically for the scrapping industry. The SCRAPPER is a fully-electronic, above-ground, low-profile vehicle scale that is durable and resistant to corrosion. The SCRAPPER is ideal for recycling centers weighing standard-size pick-up trucks and gooseneck trailers bringing in scrap metal to be recycled. The ARMOR truck scale is more suited for heavier-duty applications weighing bulk scrap metal and can withstand up to 250 truckload weighments for per day.

For weighing pallet and tote size containers during the metal separating process, Cardinal Scale offers heavy-duty industrial floor scales such as the FloorHugger and GroundForce series. The FloorHugger FHN series features extra-thick steel decks, up to 10,000 lb capacities, channel construction to protect load cells, and hermetically-sealed load cells to withstand moisture. The FloorHugger features optional ramps and pit frames for added ease of use. The GroundForce FH series electronic floor scales are great for pit installations when there is a shortage of space. The GroundForce features platforms up to 12 x 10 ft, capacities ranging from 5,000 to 20,000 lbs, hermetically-sealed waterproof load cells, and easy set-up for pit installations.

For weighing smaller recycling items such as aluminum cans, Cardinal Scale’s HSDC is a digital hanging scale that can deliver great results for recycling centers. With up to a 500 lb capacity, battery-power for portable weighing, and S hook on the bottom to hang bags of can, the HSDC is ideal when weighing smaller metal items. Whether it be large containers or smaller portions of metal products, Cardinal Scale offers a superior weighing option.

Recycling centers require truck scales, floor scales, railroad track scales, and the related weighing equipment technology that are going to be worth the investment in an environment where investments are tight. Cardinal Scale provides the most resilient, technologically-advanced truck and floor scales for vehicle and container weighing on the market today.

Learn More About Cardinal Scale Products:

https://cardinalscale.com/product

Leave a Comment

Your email address will not be published. Required fields are marked *